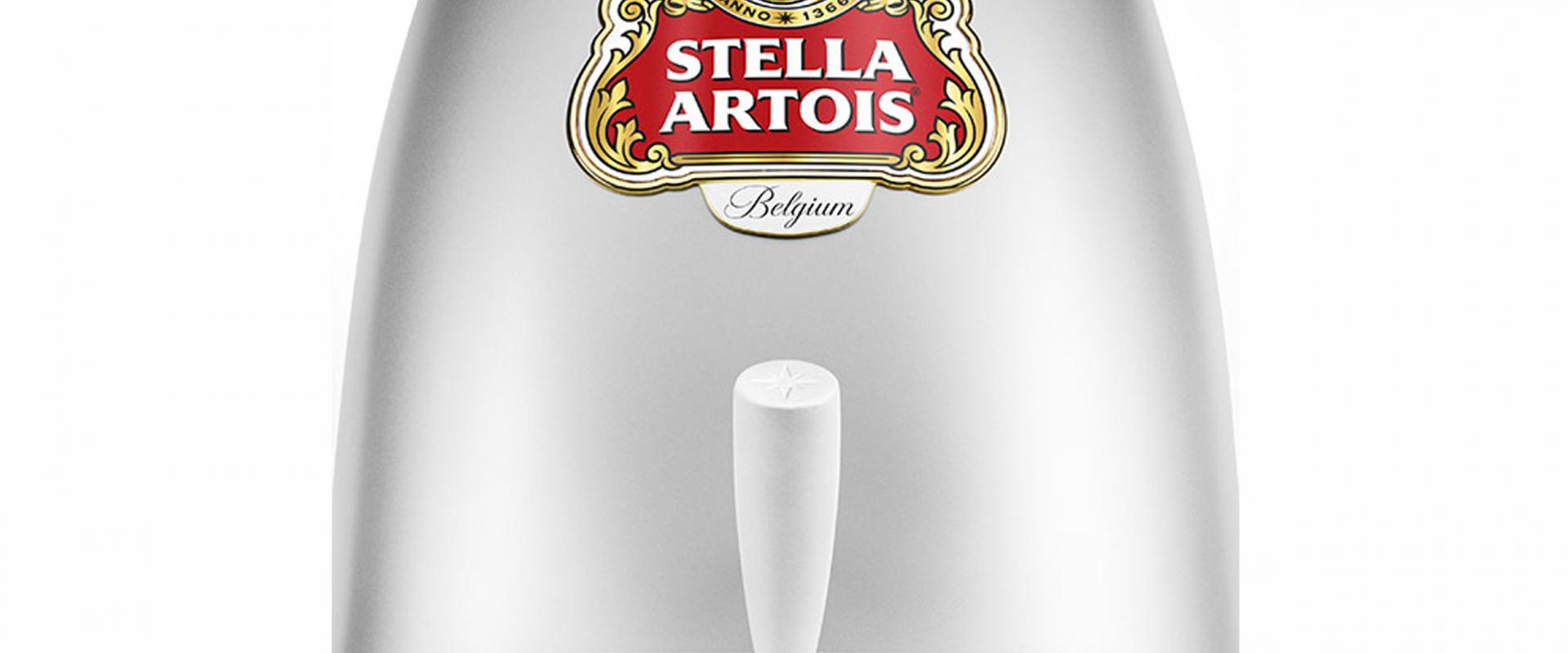

The Italian company Vin Service has been producing refrigerators and broaching equipment for beverages, beer and wine since 1976. Volpi Design Studio was asked to execute a mechanical analysis for the development of a beer tapping system: the company wanted to create two models of the same equipment, in order to sell them in different markets. Marc Thorpe designed for Vinservice one of them, exclusively for the North-American and Canadian market, while the other one had been projected for Italy and the international market, more generally.  Our specific task, as an engineering team, was the mechanical design of both the products, due to the fact that Vinservice had already done the entire research activity and the refrigeration design internally. For this reason, it was extremely important for us to work side by side with them, in order to dialog with their team of designers and technicians, to combine style and functionalities.

Our specific task, as an engineering team, was the mechanical design of both the products, due to the fact that Vinservice had already done the entire research activity and the refrigeration design internally. For this reason, it was extremely important for us to work side by side with them, in order to dialog with their team of designers and technicians, to combine style and functionalities.  We designed the aesthetic housing of the beer tapping system, finding the best solutions for the industrialization of its components, working directly with mould manufacturers and moulding operators. The main point of this collaboration was to analyse the most critical aspects of this product: with plastic injection technology there is a concrete chance that the configuration of the moulds could be altered, once the plastic cools down. In fact, cold plastic tends to shrink, creating problems in moulds filling. The project ended successfully in July 2015, while the products were launched on the market in September. View full project here

We designed the aesthetic housing of the beer tapping system, finding the best solutions for the industrialization of its components, working directly with mould manufacturers and moulding operators. The main point of this collaboration was to analyse the most critical aspects of this product: with plastic injection technology there is a concrete chance that the configuration of the moulds could be altered, once the plastic cools down. In fact, cold plastic tends to shrink, creating problems in moulds filling. The project ended successfully in July 2015, while the products were launched on the market in September. View full project here

-

-

-

Perspectives Mar 30, 2020

KITCHEN 4.0: HOW DIGITALIZATION IS CHANGING THE RULES

Technological updating and the integration of an interconnected soul are turning modern professional kitchens into a perfect example of the 4.0 industry, where the product and its super digital powers become a tool to improve working conditions, enhance productivity, monitor the processes to achieve better results and create new business models