Make the most of the latest technologies to create winning, innovative products.

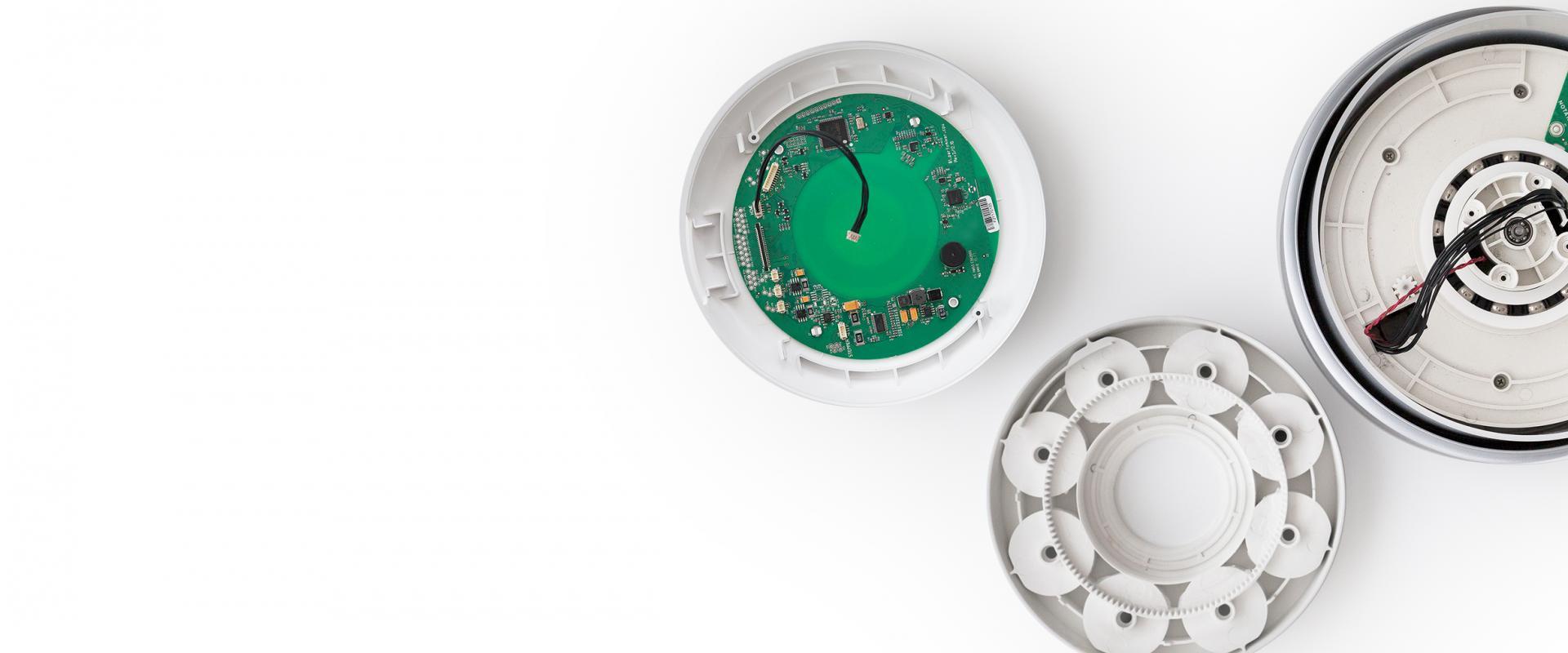

Our mechanical lab has grown into the Innovation Lab: a physical place where digital technologies are tested and developed in order to reach the highest control levels and usability. Despite our passion for technology itself, we strongly believe that it must fulfill real human needs and create outstanding human experiences.

A doer approach

We constantly research and keep up-to-speed of what is needed in terms of new technologies, electronics, mechanics and software in order to transform every project in a winning product. While understanding the project, we estimate industrialization time and costs, and look for performance optimization opportunities too.

From the idea to the thing

The possible scenarios are defined, selected and prototyped. We deliver personalized solutions working side by side with the client: through physical or virtual prototyping, we assess technical solutions and aesthetics, in order to select and define the best performing outcome.

Ensuring safety

To be present on the global market means to provide greatest guarantee on products. Thanks to our direct contacts with the certification authorities we partner with, we prepare all the necessary documentation from the early stages and provide a reactive, immediate and efficient response to potential complications or requirements.

Effortless go-to-market process

We bring you the people that will infuse the project with the most advanced technologies, and bring it to industrialization. We ensure the smoothest and most effective transition from the development stage to actual production.

-

Brewing of ideas

Saeco

A modo mio

View Case StudyOur engineering team ensured the perfect combination between aesthetics and reliability of the first true coffee machine for domestic use, as well as patenting a new coffee delivery system.

-

Playing with shadows

Paola Lenti

Shading structures

View Case StudyWe worked on technical specifications, structural tests and performance analysis for three modular shading structures for which there was no legislation.

-

The new way to tap beer

Vin Service

Tapping system

View Case StudyWe worked on the mechanical design of a beer stapler, developed it in two variants, combining aesthetics and functionality and finding alternative solutions to avoid the possible manufacturing defects of the plastic injection technology.

-

Designs that matter

Whirlpool

White goods

View Case StudySince a decade we have been collaborating with the world's leading manufacturer of home appliances. We have studied and implemented engineering and design solutions with innovative features.